1. ņä£ ļĪĀ

ļ¼┤ņĀĢĒśĢ ĻĖłņåŹ ņé░ĒÖöļ»ł ļ░śļÅäņ▓┤(amorphous metal-oxide semiconductor)ļŖö 1996ļģäļÅäņŚÉ Hosono ĒīĆņŚÉņä£ ļ░£Ēæ£ĒĢ£ ņØ┤ĒøäņŚÉ Ļ┤äļ¬®ĒĢĀ ļ¦īĒĢ£ ņŚ░ĻĄ¼Ļ▓░Ļ│╝ņÖĆ ņāüņŚģņĀüņØĖ Ļ░£ļ░£ņØ┤ ņ¦äĒ¢ēļÉśņ¢┤ ņÖöļŗż. ĻĖłņåŹņé░ĒÖöļ¼╝ ļ░śļÅäņ▓┤Ļ░Ć ņØ┤ļĀćĻ▓ī Ļ░üĻ┤æņØä ļ░øņØĆ ņØ┤ņ£ĀļŖö Ēśäņ×¼ ņĢĪņĀĢ ļööņŖżĒöīļĀłņØ┤ņŚÉ ņé¼ņÜ®ļÉśļŖö a-Si TFTņŚÉ ļ╣äĻĄÉĒĢśņŚ¼ ņÜ░ņłśĒĢ£ ĒŖ╣ņä▒ņØä ļ│┤ņØ┤Ļ│Ā, LTPS (low temperature polysilicon)ņŚÉ ļ╣äĒĢśņŚ¼ļŖö ņāüļīĆņĀüņ£╝ļĪ£ ļé«ņØĆ ņś©ļÅäņŚÉņä£ ļŗżņ¢æĒĢ£ ĻĖ░ĒīÉņŚÉ ņĀ£ņ×æņØ┤ Ļ░ĆļŖźĒĢśĻĖ░ ļĢīļ¼ĖņØ┤ļŗż.

ņØ┤ļōż ĻĖłņåŹņé░ĒÖöļ¼╝ ļ░śļÅäņ▓┤ņØś ņóģļźśļĪ£ņä£ļŖö In2O3, IGZO, ZnO, ZnSnO (ZTO), InZnO (IZO) ļō▒ņØś ļ¦ÄņØĆ ņØ┤ņä▒ļČäĻ│äņÖĆ ļŗżņä▒ļČäĻ│äņØś ĒÖöĒĢ®ļ»łļōżņØ┤ ņ׳ļŗż[1-2]. ĒŖ╣Ē׳ ņĄ£ĻĘ╝ņØś ļööņŖżĒöīļĀłņØ┤ņé░ņŚģņØś ļ░£ļŗ¼ļĪ£ ņØĖĒĢśņŚ¼ ņØ┤ļź╝ ņé░ĒÖöļ¼╝ ļ░śļÅäņ▓┤Ļ░Ć ļööņŖżĒöīļĀłņØ┤ņÜ®ņØś ĻĄ¼ļÅÖņåīņ×ÉļĪ£ņä£ ņé¼ņÜ®ĒĢśĻĖ░ ņŗ£ņ×æĒĢśņśĆļŗż. ņĄ£ņ┤łņØś ņāüņÜ®ĒÖöļŖö SharpņŚÉņä£ In-Ga-Zn-oxide (IGZO) Ļ│äņØś ļ¼┤ņĀĢĒśĢ ĻĖłņåŹņé░ĒÖöļ¼╝ ļ░śļÅäņ▓┤ļź╝ ņĢĪņĀĢļööņŖżĒöīļĀłņØ┤(liquid crystal display, LCD)ņŚÉ ņé¼ņÜ®ĒĢśņŚ¼ Apple ņé¼ņŚÉ ļé®ĒÆłĒĢ£ Ļ▓āņ£╝ļĪ£, ĻĘĖ ņØ┤ĒøäņŚÉļŖö LGļź╝ ņżæņŗ¼ņ£╝ļĪ£ ņØ┤ ņåīņ×Éļź╝ OLEDņŚÉ ņé¼ņÜ®ĒĢśņŚ¼ OLED panelņØä ņ¢æņé░ĒĢśĻ│Ā ņ׳ļŗż. ļśÉĒĢ£ ļööņŖżĒöīļĀłņØ┤ņØś Ēī©ļäÉņØś backplaneņŚÉ ņé¼ņÜ®ļÉśļŖö thin-film transistor (TFT)ļĪ£ņä£ ļŗżņ¢æĒĢ£ ņĀäņ×Éņåīņ×ÉļĪ£ņØś ņĀüņÜ®Ļ│╝ Ļ░£ļ░£ņØä ņ£äĒĢśņŚ¼ ļŹöņÜ▒ ļ¦ÄņØĆ Ļ┤ĆļĀ© ļģ╝ļ¼ĖņØś ļ░£Ēæ£Ļ░Ć ņ¦äĒ¢ēļÉśĻ│Ā ņ׳ļŗż.

ĒĢ£ĒÄĖ ņĄ£ĻĘ╝ņŚÉļŖö ļööņŖżĒöīļĀłņØ┤ Ēī©ļäÉņØ┤ ņ£ĀņŚ░ņä▒ņØä Ļ░¢Ļ│Ā, ņØ┤ļź╝ ņØ┤ņÜ®ĒĢ£ ņ£ĀņŚ░ĒĢ£ ņĀäņ×Éņåīņ×ÉĻ░Ć ļō▒ņןĒĢśĻ│Ā ņ׳ļŖöļŹ░ ņØ┤ļź╝ ņ£äĒĢ┤ņä£ļŖö ņ£ĀņŚ░ĒĢ£ ĻĖ░ĒīÉĻ│╝ ĻĘĖņŚÉ ņĀüĒĢ®ĒĢ£ ĒŖĖļ×£ņ¦ĆņŖżĒä░ņØś Ļ│ĄņĀĢĻ│╝ ĻĖ░ņłĀņØ┤ ĒĢäņÜöĒĢśļŗż. Ēśäņ×¼ ĻĖłņåŹ ņé░ĒÖöļ¼╝ TFTļź╝ ņĀ£ņ×æĒĢśĻĖ░ ņ£äĒĢ┤ ņé¼ņÜ®ļÉśļŖö Ļ│ĄņĀĢĻĖ░ņłĀņØĆ sputter, plasma enhanced chemical vapor deposition, evaporator ļō▒ņØś ņ¦äĻ│ĄĻĖ░ņłĀņØ┤Ļ│Ā, ļśÉĒĢ£ ņ”Øņ░® ņØ┤ĒøäņŚÉ Ēī©Ēä┤ņØä ĒśĢņä▒ĒĢśĻĖ░ ņ£äĒĢ£ ĒżĒåĀ ļ”¼ņåīĻĘĖļלĒöĮ ĻĖ░ņłĀņØä ņé¼ņÜ®ĒĢ┤ņĢ╝ ĒĢ£ļŗż. ņØ┤ļŖö Ļ│Āņś©ņØś ņŚ┤ņ▓śļ”¼, ņłś ļ¦ÄņØĆ ņןļ╣ä, ĻĘĖļ”¼Ļ│Ā ĒÖöĒĢÖļ¼╝ņ¦łņØ┤ ņłśļ░śļÉśļ®░ Ļ│ĄņĀĢņŗ£Ļ░äņØ┤ ļ¦ÄņØ┤ ĒĢäņÜöĒĢ£ Ļ│ĀĻ░ĆņØś Ļ│ĄņĀĢņØ┤ ļÉ£ļŗż. ļö░ļØ╝ņä£ ņĀĆņś©ņ£╝ļĪ£ ļ░śļÅäņ▓┤ļź╝ ĒśĢņä▒ĒĢĀ ņłś ņ׳ļŖö ņāłļĪ£ņÜ┤ Ļ│ĄņĀĢĻĖ░ņłĀņØ┤ ņÜöĻĄ¼ļÉ£ļŗż. ņØĖņćäĻ│ĄņĀĢņØĆ ņāüņś©Ļ│╝ ņāüņĢĢņŚÉņä£ ņ¦äĒ¢ēļÉśļŖö Ļ│ĄņĀĢņ£╝ļĪ£ Ēī©Ēä┤ņØś ĒśĢņä▒ņØä ņ£äĒĢ£ ļ│äļÅäņØś Ļ│ĀĻ░Ćņןļ╣äĻ░Ć ĒĢäņÜöĒĢśņ¦Ć ņĢŖĻ│Ā, ņĀĆļĀ┤ĒĢ£ Ļ░ĆĻ▓®ņ£╝ļĪ£ ņāØņé░ņØ┤ Ļ░ĆļŖźĒĢśĻ│Ā, ļśÉĒĢ£ ņāüļīĆņĀüņ£╝ļĪ£ ņ╣£ ĒÖśĻ▓ĮņĀüņØĖ Ļ│ĄņĀĢņØ┤ļŗż. ļ¦ÄņØĆ ņØĖņćäĻ│ĄņĀĢņØ┤ ņ׳ņ£╝ļéś ĻĘĖņżæņŚÉ ļīĆĒæ£ņĀüņØĖ Ļ▓āņ£╝ļĪ£ļŖö ņ×ēĒü¼ņĀ» (inkjet)Ļ│ĄņĀĢĻ│╝ ņĀäĻĖ░ņłśļĀźĒĢÖņĀ» Ļ│ĄņĀĢ (electrohydrodynamic jet)ņØ┤ ņ׳ļŗż[3-5].

ņ×ēĒü¼ņĀ»Ļ│ĄņĀĢņØä ņØ┤ņÜ®ĒĢ£ ĻĖłņåŹņé░ĒÖöļ¼╝ TFTņŚÉ ļīĆĒĢ£ ņŚ░ĻĄ¼ļŖö ņŚ¼ļ¤¼ ņŚ░ĻĄ¼ĒīĆņŚÉņä£ ļŗżņ¢æĒĢśĻ▓ī ņØ┤ļŻ©ņ¢┤ņĀĖ ņÖöļŗż. ņĄ£ĻĘ╝ņŚÉ Lee ļō▒ņØĆ inkjetņØä ņØ┤ņÜ®ĒĢ£ ņØĖļööņøĆ ņé░ĒÖöļ¼╝ņØä ņŚ░ĻĄ¼ĒĢśņŚ¼ ļé«ņØĆ Ļ│ĄņĀĢņś©ļÅäņŚÉņä£ ņÜ░ņłśĒĢ£ ņŚ░ĻĄ¼ Ļ▓░Ļ│╝ļź╝ ļé┤ ļåōņĢśļŗż[6]. TFTņØś ņØ┤ļÅÖļÅäĻ░Ć 1.83 cm2/V s, On-to-off ņĀäļźśĒŖ╣ņä▒ļŖö 108, ļ¼ĖĒä▒ņĀäņĢĢņØĆ -1.9 V, ĻĘĖļ”¼Ļ│Ā subthreshold slopeņØĆ 0.3 V/dec-1ņØś ĒŖ╣ņä▒ņØä ļ░£Ēæ£ĒĢśņśĆļŗż. ņĢäņŚ░ĻĖ░ļ░śņØś ĻĖłņåŹņé░ĒÖöļ¼╝ ņżæņŚÉ IZOļŖö ļ░śļÅäņ▓┤ļŖö ļ¼╝ļĪĀņØ┤Ļ│Ā Ēł¼ļ¬ģņĀäĻĘ╣ņ£╝ļĪ£ļÅä ņé¼ņÜ®ņØ┤ Ļ░ĆļŖźĒĢ£ ņåīņ×¼ņØ┤ĻĖ░ņŚÉ ņŻ╝ļ¬®ļ░øļŖö ņé░ĒÖöļ¼╝ļ░śļÅäņ▓┤ņØ┤ļŗż. ņŚ░ĻĄ¼ņ×ÉļōżņØĆ IZOņŚÉ Ļ┤Ćņŗ¼ņØä Ļ░Ćņ¦ĆĻ│Ā ņŚ░ĻĄ¼ļź╝ ņ¦äĒ¢ēĒĢśņśĆļŗż. Sol-gel Ļ│ĄņĀĢņ£╝ļĪ£ ņĀ£ņ×æĒĢ£ IZO TFTļŖö 300 ┬░CņØś Ļ│ĄņĀĢņś©ļÅäņŚÉņä£ 0.54 cm2/V sņØś ņØ┤ļÅÖļÅäņÖĆ 107ņØś ņĀĢļźśĒŖ╣ņä▒ņØä ļéśĒāĆļé┤ņŚłļŗż[7]. ĻĘĖļ¤¼ļéś ļ│Ė ņŚ░ĻĄ¼ņŗżņŚÉņä£ ņ▓śņØīņ£╝ļĪ£ 200 ┬░CņØś inkjet Ļ│ĄņĀĢņØä ņØ┤ņÜ®ĒĢ£ IZO TFTļź╝ ņĀĆņś©ņŚÉņä£ ņĀ£ņ×æĒĢśņŚ¼ ņØ┤ļÅÖļÅäĻ░Ć 0.45 cm2/V s, ņĀäļźśĒŖ╣ņä▒ļŖö 105, ļ¼ĖĒä▒ņĀäņĢĢņØĆ 7.0 V, ĻĘĖļ”¼Ļ│Ā subthreshold slopeņØĆ 0.5 V/dec-1ņØś ĒŖ╣ņä▒ņØä ļ░£Ēæ£ĒĢśņśĆļŗż[8].

ņé░ĒÖöļ¼╝TFTņØś ņĀäĻĖ░ņĀüĒŖ╣ņä▒ņØä Ē¢źņāüņŗ£ĒéżĻĖ░ ņ£äĒĢśņŚ¼ ļÅäĒĢæņØś ĒÜ©Ļ│╝ņŚÉ ļīĆĒĢ£ ņŚ░ĻĄ¼Ļ░Ć ĒÖ£ļ░£ĒĢśĻ▓ī ņ¦äĒ¢ēļÉśĻ│Ā ņ׳ļŗż. ļÅäĒĢæņØś ņåīņ×¼ļĪ£ļŖö ņĢīņ╣┤ļ”¼ĻĖłņåŹņØä ĒżĒĢ©ĒĢ£ ļŗżņ¢æĒĢ£ ņé░ĒÖöļ¼╝ TFTņÜ® ĻĖłņåŹļōżņØ┤ ņé¼ņÜ®ļÉśĻ│Ā ņ׳ļŖöļŹ░ ņØ┤ļŖö charge carrier ļåŹļÅäļź╝ ļåÆņØ┤ļŖö ĒÜ©Ļ│╝Ļ░Ć ņ׳ĻĖ░ ļĢīļ¼ĖņØ┤ļŗż[9]. ļīĆĒæ£ņĀüņ£╝ļĪ£ļŖö Ga, Al, Hf, Zrļō▒ņØä ņé¼ņÜ®ĒĢśņŚ¼ ņĀäĻĖ░ņĀü ĒŖ╣ņä▒ņØś Ē¢źņāüņØä ĻĖ░ļīĆĒĢśņśĆļŗż. ĒĢ£ĒÄĖ ZrņØä ļÅäĒĢæĒĢ£ Ļ▓ĮņÜ░ņŚÉļŖö ņä£ļĪ£ ļŗżļźĖ Ļ▓ĮņÜ░Ļ░Ć ļ░£Ēæ£ļÉśņŚłļŖöļŹ░, ļŗ©ņł£ĒĢśĻ▓ī ņĀüņĀĢļ¤ēņØä ļÅäĒĢæĒĢśļŖö Ļ▓ĮņÜ░ņŚÉļŖö ņĀäĻĖ░ņĀü ĒŖ╣ņä▒ņØ┤ ļé«ņĢäņ¦ĆļŖö ļ│┤Ļ│ĀĻ░Ć ņ׳ņ£╝ļéś[10], ļÅäĒĢæņØś ļåŹļÅäļź╝ ļ»ĖņäĖĒĢśĻ▓ī ņĪ░ņĀĢĒĢĀ Ļ▓ĮņÜ░ņŚÉļŖö ĒŖ╣ņĀĢ ļÅäĒĢæņØś ļåŹļÅäņŚÉņä£ ņĀäĻĖ░ņĀü ĒŖ╣ņä▒ņØä Ē¢źņāüņŗ£ĒéżļŖö ĒØźļ»ĖļĪ£ņÜ┤ Ļ▓░Ļ│╝ļÅä ļ░£Ēæ£ļÉśņŚłļŗż[11]. ĒĢ£ĒÄĖ ņĀĆņś©ņØś Ļ│ĄņĀĢņś©ļÅäņŚÉņä£ļŖö Gaļź╝ ļÅäĒĢæĒĢśņŚ¼ ņé░ĒÖöļ¼╝ In2O3 TFTļź╝ ņĀ£ņ×æĒĢśņśĆņ£╝ļéś TFT ĒŖ╣ņä▒Ļ░ÆņØä Ļ│ĄņĀĢņś©ļÅäĻ░Ć 200 ┬░C ņŚÉņä£ļŖö ņĀäĒśĆ ņ¢╗ņ¦Ć ļ¬╗ĒĢśņśĆļŗż[12].

ņĄ£ĻĘ╝ņŚÉ ņĀĆņ×ÉļŖö ņĢäņŚ░ņØ┤ ļÅäĒĢæļÉ£ In2O3 TFTļź╝ ļ│┤Ļ│ĀĒĢśņŚ¼ 200 ┬░C Ļ│ĄņĀĢņś©ļÅäņŚÉņä£ļÅä TFTĒŖ╣ņä▒Ļ░ÆņØä ņ¢╗ņŚłļŗż. ĻĘĖļ¤¼ļéś ņĢäņŚ░ņŚÉ ņØśĒĢ£ ļÅäĒĢæņØĆ ļåŹļÅäĻ░Ć ņ”ØĻ░ĆĒĢ©ņŚÉ ļö░ļØ╝ņä£ TFT ĒŖ╣ņä▒ņØ┤ ĒśäņĀĆĒ׳ ņĀĆĒĢśĒĢśļŖö Ļ▓āņØä ļ░£Ļ▓¼ĒĢśņśĆļŗż[13].

ņĢīņ╣┤ļ”¼ĻĖłņåŹ ņżæņŚÉņä£ LithiumņØĆ ņ×æņØĆ ļ░śĻ▓ĮĻ│╝ ņé░ņåīņØ┤ņś©Ļ│╝ņØś Ļ▓░ĒĢ®ņŚÉļäłņ¦ĆļĪ£ ņØĖĒĢśņŚ¼ ņé░ĒÖöļ¼╝ TFTņØś ĒŖ╣ņä▒ņŚÉņä£ ņØ┤ļÅÖļÅäņØś ņŚŁĒĢĀņØä ņŻ╝ļŖö ņżæņÜöĒĢ£ ņøÉņåīņØ┤ļŗż. ņĄ£ĻĘ╝ņŚÉ Liļź╝ ļÅäĒĢæĒĢśņŚ¼ ņÜ®ņĢĪĻ│ĄņĀĢņ£╝ļĪ£ ņé░ĒÖöļ¼╝ TFTļź╝ ņĀ£ņ×æĒĢśņŚ¼ ņĀäĻĖ░ņĀü ĒŖ╣ņä▒ņØä Ē¢źņāüņŗ£Ēé© ņŚ░ĻĄ¼Ļ░Ć ļ│┤Ļ│Ā ļÉśņŚłļŗż[9,14]. ĒĢ£ĒÄĖ ņØ┤ļ¤¼ĒĢ£ ņé░ĒÖöļ¼╝ņŚÉ ņśüĒ¢źņØä ņŻ╝ļŖö ļÅäĒĢæĒÜ©Ļ│╝ņŚÉ ļīĆĒĢ£ ņŚ░ĻĄ¼Ļ░Ć ņ¦äĒ¢ēļÉśĻ│Ā ņ׳ņ£╝ļéś inkjetĻ│ĄņĀĢņØä ņØ┤ņÜ®ĒĢ£ ņĀĆņś©ņŚÉņä£ņØś ņé░ĒÖöļ¼╝ TFTņØś ņĀ£ņ×æņŚÉ ņ׳ņ¢┤ņä£ ļÅäĒĢæ ņśüĒ¢źņØä ņŚ░ĻĄ¼ĒĢ£ Ļ▓ĮņÜ░ļŖö ļ¦Äņ¦Ć ņĢŖļŗż. ļö░ļØ╝ņä£ ņ£äņØś Ļ░£ļģÉņØä inkjet Ļ│ĄņĀĢņŚÉ ņĀüņÜ®ĒĢśņŚ¼ ņĀĆņś©ņŚÉņä£ņØś ņé░ĒÖöļ¼╝TFTņØś ņĀ£ņ×æ Ļ░ĆļŖźņä▒ņØä ĒÖĢņØĖĒĢśĻ│Ā, ļŗżņ¢æĒĢ£ ņś©ļÅäņŚÉņä£ ņĀ£ņ×æĒĢ£ ņé░ĒÖöļ¼╝TFT ņåīņ×Éļź╝ ĒåĄĒĢ┤ ņĀäĒĢśņØś ļČĆĒĢśņŚÉ ļö░ļźĖ ĒŖ╣ņä▒ņØä Ļ│Āņ░░ĒĢśĻ│Āņ×É ĒĢ£ļŗż.

2. ņŗżĒŚś ļ░®ļ▓Ģ

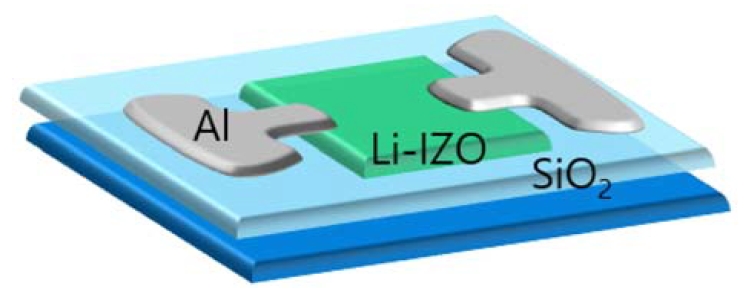

ņé░ĒÖöļ¼╝ļ░śļÅäņ▓┤ ņÜ®ņĢĪņØä ļ¦īļōżĻĖ░ ņ£äĒĢśņŚ¼ 0.3 MņØś zinc acetate dihydrateņÖĆ indium nitrate hydrateļź╝ 2-methoxy ethanolņŚÉ ņÜ®ĒĢ┤ĒĢśņśĆĻ│Ā, ļÅäĒĢæņØä ņ£äĒĢśņŚ¼ 0.01, 0.05, ĻĘĖļ”¼Ļ│Ā 0.1MņØś lithiumļź╝ ņ▓©Ļ░ĆĒĢśņŚ¼ ņāüņś©ņŚÉņä£ 24ņŗ£Ļ░ä ĻĄÉļ░śĒĢśņŚ¼ ņÜ®ņĢĪņØä ņĀ£ņĪ░ĒĢśņśĆļŗż. ņØĖņćäļź╝ ņ£äĒĢśņŚ¼ ņÜ®ņĢĪņØä ņ╣┤ĒŖĖļ”¼ņ¦ĆņŚÉ ļäŻņ¢┤ ņĢĢņĀäĒśĢ inkjet printer (Omnijet Mini-100, Unijet)ņŚÉ ņäżņ╣śĒĢśņśĆļŗż. ņØ┤ļĢīņØś ņ×ēĒü¼ņĀ» Ēöäļ”░Ēä░ņØś Ļ│ĄņĀĢņĪ░Ļ▒┤ņØä ņĪ░ņĀłĒĢśņŚ¼ ĻĘĀņØ╝ĒĢ£ ņ×ēĒü¼ņØś ņĢĪņĀüņØä ņ¢╗ĻĖ░ ņ£äĒĢśņŚ¼ 500 HzņØś ņŻ╝ĒīīņłśņÖĆ 60 VņØś ņĀäņĢĢņ£╝ļĪ£ 0.5 mmņØś ļåÆņØ┤ņŚÉņä£ ļģĖņ”ÉņØś ĻĄ¼Ļ▓ĮņØ┤ 50 ╬╝mļĪ£ ĒåĀņČ£ (jetting) ĒĢśņśĆļŗż. ĻĖ░ĒīÉņØś ņś©ļÅäņØś ņśüĒ¢źņØä ĒÖĢņØĖĒĢśĻĖ░ ņ£äĒĢ┤ 25, 47, ĻĘĖļ”¼Ļ│Ā 57 ┬░CļĪ£ ļ│ĆĒÖöĒĢśņŚ¼ ĒåĀņČ£ĒĢśņśĆļŗż. Ļ▓īņØ┤ĒŖĖ ņĀłņŚ░ņ▓┤ļĪ£ļŖö heavily doped silicon ĻĖ░ĒīÉņ£äņŚÉ SiO2ļź╝ ņŚ┤ņé░ĒÖöļĪ£ ĒśĢņä▒ĒĢśņŚ¼ bottom-gateņÖĆ top-contactĻĄ¼ņĪ░ņØś TFTļź╝ ņĀ£ņ×æĒĢśņśĆļŗż (ĻĘĖļ”╝ 1). Ļ│ĄņĀĢņĀäņŚÉ ĻĖ░ĒīÉņØś ņäĖņĀĢņØĆ IPAņÖĆ ņ┤łņØīĒīīļĪ£ ņ¦äĒ¢ēĒĢśņśĆĻ│Ā, ĻĖ░ĒīÉņØś ņĀäņ▓śļ”¼ļĪ£ļŖö UV/O3ļź╝ 20ļČäĻ░ä ņŗ£Ē¢ēĒĢ£ ĒøäņŚÉ ĻĖłņåŹņé░ĒÖöļ¼╝ ņÜ®ņĢĪņØä inkjet printerļź╝ ņé¼ņÜ®ĒĢśņŚ¼ ĒåĀņČ£ĒĢśņśĆļŗż. ļ░Ģļ¦ēņØĆ 150 ┬░CņŚÉņä£ 1 ļČäĻ░ä ņÜ®ļ¦żļź╝ ņ”Øļ░£ĒĢśĻ│ĀļŖö 200 ┬░CņŚÉņä£ 400 ┬░CĻ╣īņ¦Ć ņŚ┤ņ▓śļ”¼ĒĢśņŚ¼ ļÅäĒĢæļÉ£ ņé░ĒÖöļ»ł ļ░śļÅäņ▓┤ļź╝ ņĀ£ņ×æĒĢśņśĆļŗż. TFTņŚÉņä£ļŖö ņĢīļŻ©ļ»ĖļŖäņØä ņåīņŖżņÖĆ ļō£ļĀłņØĖ (source and drain)ņ£╝ļĪ£ļŖö ņé¼ņÜ®ĒĢśĻĖ░ņ£äĒĢśņŚ¼ ņŚ┤ņ”Øņ░®ĻĖ░ļĪ£ 10-6 TorrņŚÉņä£ ņ▒äļäÉņØś ĒÅŁĻ│╝ ĻĖĖņØ┤ļŖö 1500 ╬╝mņÖĆ 100 ╬╝mņØĖ 100 nmļæÉĻ╗śļĪ£ ņ”Øņ░®ĒĢśņśĆļŗż. ļ░Ģļ¦ēņØś ĒŖ╣ņä▒ĒÅēĻ░ĆļĪ£ļŖö differential scanning calorimetry/thermogravimetric analysis (DSC/TGA) ļČäņäØņØä ĒĢśņŚ¼ ņŚ┤ņĀü ĒŖ╣ņä▒ Ļ│ĪņäĀ (thermogram)ņØä ņ¢╗ņŚłļŗż. TFTņØś ĒŖ╣ņä▒ĒÅēĻ░ĆļŖö ņĢĮ 15Ļ░£ ļé┤ņÖĖņØś ņŗ£ļŻīļź╝ parameter analyzer (Keithley 4200)ļź╝ ņé¼ņÜ®ĒĢśņŚ¼ I-V (current-voltage)ļź╝ ņĖĪņĀĢĒĢśņśĆņ£╝ļ®░ ĒÅēĻĘĀĻ░Æņ£╝ļĪ£ ņĘ©ĒĢśņśĆļŗż. ņ¢æņĀäĒĢś ļČĆĒĢś ņĢłņĀĢņä▒ ņŗżĒŚś(positive bias stress stability)ņØĆ Ļ▓īņØ┤ĒŖĖ ņĀäņĢĢņØä 20 VļĪ£ Ļ│ĀņĀĢĒĢśņŚ¼ 0ņ┤łņŚÉņä£ 3600ņ┤łĻ╣īņ¦Ć ņŗżņŗ£ĒĢśņśĆļŗż. X-ray photoelectron spectroscopy (XPS, Thermo VG ESCA Sigma Probe) ļČäņäØņØĆ ņøÉņåīļź╝ ļČäņäØĒĢśĻĖ░ ņ£äĒĢśņŚ¼ ņ¦äĒ¢ēĒĢśņśĆĻ│Ā, ņØ┤ļĢī monochromic Al Ka sourceļź╝ ņé¼ņÜ®ĒĢśļ®░ 100W/15 kVņŚÉņä£ ĒĢśņśĆĻ│Ā, ĻĄÉņĀĢņØĆ C 1s peakļĪ£ ņ¦äĒ¢ēĒĢśņśĆļŗż.

3. Ļ▓░Ļ│╝ ļ░Å Ļ│Āņ░░

ņÜ®ņĢĪĻ│ĄņĀĢņØś ņé░ĒÖöļ¼╝ļ░śļÅäņ▓┤ļź╝ ņØ┤ņÜ®ĒĢ£ ņé░ĒÖöļ¼╝ TFTļŖö Ļ│Āņä▒ļŖźņØś ņåīņ×ÉņÖĆ ļé«ņØĆ Ļ│ĄņĀĢņś©ļÅäņØś ļæÉĻ░Ćņ¦Ć ņśüņŚŁņŚÉņä£ ņŚ░ĻĄ¼Ļ░Ć ņ¦äĒ¢ēļÉśĻ│Ā ņ׳ļŗż. ņĪĖ-Ļ▓ö (sol-gel) ļ░śņØæņØä ņØ┤ņÜ®ĒĢ£ ņÜ®ņĢĪĻ│ĄņĀĢņ£╝ļĪ£ ņĀ£ņĪ░ļÉ£ ĻĖłņåŹ ņé░ĒÖöļ¼╝ ņÜ®ņĢĪņØĆ ņŚ┤ ņ▓śļ”¼ Ļ│╝ņĀĢņØä ĒåĄĒĢśņŚ¼ ĻĖłņåŹņé░ĒÖöļ¼╝ ļ░Ģļ¦ēņ£╝ļĪ£ ļ░śņØæņØ┤ ņØ╝ņ¢┤ļéśņä£ ļ│ĆĒÖöļÉ£ļŗż. ļö░ļØ╝ņä£ ļīĆļČĆļČäņØś ņÜ®ņĢĪĻ│ĄņĀĢņØĆ ņé░ĒÖöļ¼╝ļ░śļÅäņ▓┤ļź╝ ļ¦īļōżĻĖ░ ņ£äĒĢśņŚ¼ ņĢĮ 400-500 ┬░CņØś Ļ│ĄņĀĢ ņś©ļÅäļź╝ ņ▒äĒāØĒĢ£ļŗż. ņØ┤ļŖö ņĀĆņś©ņØś Ļ▓ĮņÜ░ņŚÉ ņāØņä▒ĒĢĀ ņłś ņ׳ļŖö ņ£ĀĻĖ░ļ¼╝ ļō▒ņØś ņ×öņŚ¼ļ¼╝ņ¦łņØä ņÖäņĀäĒ׳ ņĀ£Ļ▒░ĒĢśĻ│Ā ņś©ņĀäĒĢ£ ĻĖłņåŹ-ņé░ĒÖöļ¼╝ ĻĄ¼ņĪ░ļź╝ ņ¢╗ņØä ņłś ņ׳ĻĖ░ ļĢīļ¼ĖņØ┤ļŗż. ļö░ļØ╝ņä£ ņØ┤ļ│┤ļŗż ļé«ņØĆ Ļ│ĄņĀĢņś©ļÅäļĪ£ ļ░Ģļ¦ēņØä ĒśĢņä▒ĒĢśļŖö Ļ▓ĮņÜ░ļŖö ļ░śļÅäņ▓┤ņåīņ×ÉņØś ĒŖ╣ņä▒ņØä ņĀ£ļīĆļĪ£ ļ¬╗ ņ¢╗Ļ▒░ļéś, ĻĘĖ ĒŖ╣ņä▒ņØ┤ ņĀäĒśĆ ļ░£Ļ▓¼ļÉśņ¦Ć ņĢŖļŖö Ļ▓ĮņÜ░Ļ░Ć ļ¦Äļŗż[12]. ĻĘĖļ¤¼ļ»ĆļĪ£ ņĀĆņś©ņØś Ļ│ĄņĀĢņś©ļÅäņŚÉ ļīĆĒĢ£ ņŚ░ĻĄ¼ļŖö ļ¦Äņ¦Ć ņĢŖļŗż. ĻĘĖļ¤¼ļéś ļ│Ė ņĀĆņ×ÉļŖö inkjet processņŚÉņä£ļŖö ļé«ņØĆ ņś©ļÅäņŚÉņä£ļÅä ļ│┤ļŗż Ē¢źņāüļÉ© Ļ▓░Ļ│╝ļź╝ ņ¢╗ņØä ņłś ņ׳ļŗżļŖö Ļ▓āņØä ņ”Øļ¬ģĒĢśņŚ¼ ņŚ¼ļ¤¼ ļģ╝ļ¼ĖņØä ļ░£Ēæ£ĒĢśņśĆļŗż[8]. ņØ┤ļŖö inkjet Ļ│ĄņĀĢņØś ļŗżņ¢æĒĢ£ parameterļĪ£ ņØĖĒĢśņŚ¼ ļ░Ģļ¦ēņØś ĒśĢņä▒ ļ®öņ╗żļŗłņ”śņØ┤ ļŗżļź┤Ļ▓ī ņ¦äĒ¢ēļÉśĻĖ░ ļĢīļ¼Ėņ£╝ļĪ£ ņé¼ļŻīļÉ£ļŗż. ļ│Ė ņŗżĒŚśņŚÉņä£ļŖö inkjet parameterļź╝ ņĄ£ņĀüĒÖö ĒĢ£ ĒøäņŚÉ ņ×ēĒü¼ņØś ņĢĪņĀüņØä 127-╬╝mņØś Ļ░äĻ▓®ņ£╝ļĪ£ ņŚ░ņåŹņĀüņ£╝ļĪ£ ĒåĀņČ£ĒĢśņŚ¼ ļ”¼ĒŖ¼ņØ┤ ļÅäĒĢæļÉ£ ņé░ĒÖöļ¼╝ (Li-doped IZO) ļ░Ģļ¦ēņØä ņĀ£ņ×æĒĢśņśĆļŗż.

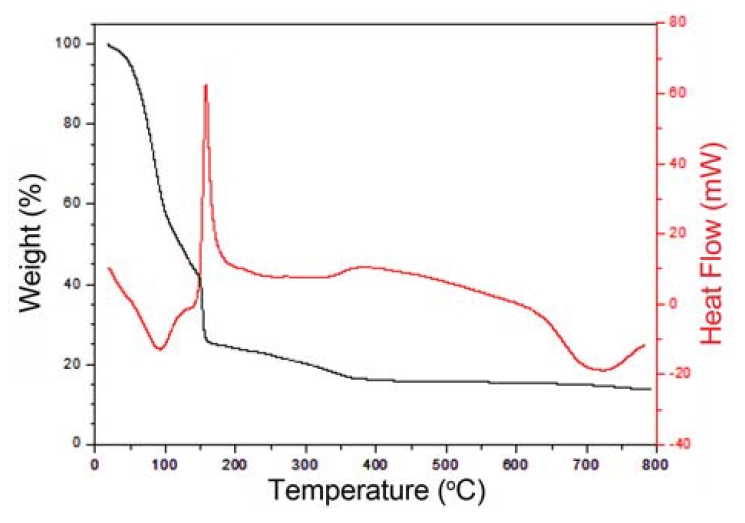

ĻĘĖļ”╝ 2ņŚÉņä£ļŖö DSC/TGA ņŚ┤ļČäņäØņØś Ļ▓░Ļ│╝ļź╝ ļ│┤ņŚ¼ņżĆļŗż. ņś©ļÅäņŚÉ ļö░ļźĖ ņŚ┤ļ¤ēņØś ļ│ĆĒÖöļź╝ ļ│┤ļ®┤ 160 ┬░CņŚÉņä£ ļ░£ņŚ┤ Ēö╝Ēü¼ļź╝ ĒÖĢņØĖĒĢśņŚ¼ ņĢī ņłś ņ׳ļŗż ņØ┤ļŖö ņÜ®ļ¦żĻ░Ć ņ”Øļ░£ĒĢśļ®┤ņä£ ļéśĒāĆļéśļŖö dehydroxylation ĒśäņāüņØ┤ļŗż. ĒØźļ»ĖļĪ£ņÜ┤ Ļ▓āņØĆ ļÅäĒĢæņØ┤ ņŚåļŖö IZOņØś Ļ▓ĮņÜ░ņŚÉļŖö ņĢĮ 168 ┬░CņŚÉņä£ ļ│Ė ĒśäņāüņØ┤ ļéśĒāĆļé£ļŗż[8]. ņØ┤ļĢīļŖö ņÜ®ļ¦żļĪ£ ņé¼ņÜ®ļÉśļŖö 2-metboxy ethanolĻ│╝ acetylacetoneņØś ļČĆļČäņĀüņØĖ ņ×ÉĻĖ░ņŚ░ņåī (self-combustion) ļ░śņØæņŚÉ ņØśĒĢ£ Ļ▓āņØ┤ļŗż. ļ│Ė ņŗżĒŚśņØś Ļ▓ĮņÜ░ņŚÉļŖö IZOņØś Ļ▓ĮņÜ░ļ│┤ļŗż ļé«ņØĆ ņś©ļÅäņŚÉņä£ ļéśĒāĆļéśļŖö dehaydroxylationņØĆ ļÅäĒĢæņŚÉ ņØśĒĢ£ Ļ▓āņ£╝ļĪ£ ņé¼ļŻīļÉ£ļŗż. ņ”ē ļÅäĒĢæĒÜ©Ļ│╝ ļö░ļØ╝ ļ░śņØæņś©ļÅäĻ░Ć ļé«ņĢäņ¦ÉņØä ņĢī ņłś ņ׳ļŗż. ņØ┤ņÖĆ Ļ░ÖņØĆ ņāüļīĆņĀüņ£╝ļĪ£ ļé«ņØĆ ņś©ļÅäļŖö ņé░ĒÖöņĀ£ļĪ£ņä£ņØś indium nitrateĻ░Ć ņÜ®ļ¦żļĪ£ ņĪ┤ņ×¼ĒĢśļŖö 2-methoxy ethanolņØä ņŚ░ļŻīļĪ£ ĒĢśņŚ¼ ņ×ÉĻ░Ć ņŚ░ņåīļ░śņØæņØ┤ ļŹö ņ┤ēņ¦äļÉśĻĖ░ ļĢīļ¼ĖņØ┤ļŗż. ņØ┤ļŖö ļÅäĒĢæņŚÉ ņØśĒĢśņŚ¼ ņāüļīĆņĀüņ£╝ļĪ£ ļé«ņØĆ ņś©ļÅäņŚÉņä£ļÅä ļ░Ģļ¦ēņØä ĒśĢņä▒ĒĢśņŚ¼ ņåīņ×ÉņØś ĒŖ╣ņä▒ņØä ņ¢╗ņØä ņłś ņ׳ņØīņØä ņØśļ»ĖĒĢ£ļŗż. ļö░ļØ╝ņä£ ņāüļīĆņĀüņ£╝ļĪ£ ņĀĆņś©ņŚÉņä£ņØś ņĀäĻĖ░ņĀü ĒŖ╣ņä▒ņØä ĻĖ░ļīĆĒĢĀ ņłś ņ׳ļŗż. ĻĘĖ ņØ┤ĒøäņØś 320 ┬░C ņØ┤ņāüņŚÉņä£ņØś ļ░£ņŚ┤ Ēö╝Ēü¼Ļ░Ć ļéśĒāĆļéśļŖöļŹ░ ņØ┤ļŖö metal-oxide ĒśĢņä▒ņŚÉ ņØśĒĢśņŚ¼ ļéśĒāĆļéśļŖö Ļ▓āņ£╝ļĪ£ ļ░śņØæņś©ļÅäņŚÉ ļö░ļźĖ ĻĖłņåŹ-ņé░ĒÖöļ¼╝ņØś ĒśĢņä▒ņØ┤ ņל ņØ┤ļŻ©ņ¢┤ņ¦ÉņØä ĒÖĢņØĖĒĢĀ ņłś ņ׳ļŗż.

ĻĘĖļ”╝ 3Ļ│╝ Table 1ņŚÉņä£ļŖö Li-doped IZO ļ░Ģļ¦ēņØś ņś©ļÅäņŚÉ ļö░ļźĖ XPS ļČäņäØĒĢ£ ņ×ÉļŻīņØ┤ļŗż. XPS spectraņŚÉņä£ ņ¢╗ņØĆ O 1s spectraļź╝ Gaussian deconvolutionņŚÉ ņØśĒĢśņŚ¼ ņäĖĻ░£ņØś ņé░ņåī peakļĪ£ ļČäļ”¼ĒĢśņśĆļŗż. ļé«ņØĆ ņś©ļÅäņØĖ 200 ┬░CņŚÉņä£ņØś ņ▓½ļ▓łņ®© peak 1ļŖö ļé«ņØĆ ļ░öņØĖļö® ņŚÉļäłņ¦Ć (binding energy)ļĪ£ņä£ 531.38 eVļź╝ ļéśĒāĆļé£ļŗż. ņØ┤ peak 1ļŖö ĻĖłņåŹĻ│╝ ņé░ņåīĻ░Ć ņÖäņĀäĒĢśĻ▓ī Ļ▓░ĒĢ®ĒĢ£ ĒśĢĒā£ļź╝ Ļ░Ćņ¦ĆļŖö ņé░ņåīņŚÉ ņØśĒĢ┤ ļéśĒāĆļéśļŖö Ļ▓āņØ┤ļŗż. ļæÉļ▓łņ¦Ė peak 2ļŖö binding energy peakļŖö 532.47 eVņŚÉņä£ ļéśĒāĆļé£ļŗż. ņØ┤ peak 2ļŖö oxygen-deficient (ņé░ņåī Ļ│ĄĒĢŹ, Ovac)ņŚÉ ņĪ┤ņ×¼ĒĢśļŖö ņé░ņåīņØ┤ņś© ļĢīļ¼ĖņŚÉ ļéśņśżļŖö Ļ▓āņ£╝ļĪ£ ņé░ņåīĻ│ĄĒĢŹ ļĢīļ¼ĖņŚÉ ņāØņä▒ļÉ£ļŗż. ņäĖļ▓łņ¦Ė peak 3ņØś bind energyļŖö 533.90 eVņŚÉņä£ ļéśĒāĆļé£ļŗż.

ņØ┤ peak 3ļŖö ļ░Ģļ¦ēĒæ£ļ®┤ņŚÉņä£ ņØ┤ļŻ©ņ¢┤ņ¦ä H2Oļéś ŌĆōOHņŚÉ Ļ┤ĆļĀ©ļÉ£ ņé░ņåīņŚÉ ņØśĒĢśņŚ¼ ļéśĒāĆļéśļŖö Ļ▓āņØ┤ļŗż (-OH group). ņØ┤ļōżņØś ņé░ņåīņØś ļ╣äņ£©ņØä ņé┤Ēæ£ļ│┤ļ®┤ peak 1Ļ│╝ peak 3ļŖö 38.38% ĻĘĖļ”¼Ļ│Ā 17.27%ņØ┤ļŗż. ņŚ┤ņ▓śļ”¼ ņś©ļÅäĻ░Ć 200 ┬░CņŚÉņä£ 300 ┬░CļĪ£ ņś¼ļØ╝Ļ░Ćļ®┤ Peak 2Ļ░Ć 38.38%ņŚÉņä£ 31.47%ļĪ£ Ļ░ÉņåīĒĢśĻ│Ā, Peak 3ņØś ņ¢æņØĆ 17.27%ņŚÉņä£ 10.27%ļĪ£ Ļ░ÉņåīĒĢśļŖö Ļ▓āņØä ņĢī ņłś ņ׳ļŗż. ņ”ē ņś©ļÅäĻ░Ć ņāüņŖ╣ĒĢ©ņŚÉ ļö░ļØ╝ņä£ ņāüļīĆņĀüņ£╝ļĪ£ Peak 1ļŖö ņ”ØĻ░ĆĒĢśļŖöļŹ░, ņØ┤Ļ▓āņØĆ ņś©ļÅäņŚÉ ļö░ļźĖ ĻĖłņåŹĻ│╝ ņé░ĒÖöļ¼╝ Ļ░äņØś ļ░śņØæņŚÉ ņØśĒĢśņŚ¼ ĻĖłņåŹņé░ĒÖöļ¼╝ņØś Ļ▓░ĒĢ® ĒśĢņä▒ņØ┤ ļ¦ÄņĢä ņ¦ĆļŖö Ļ▓āņØ┤ļŗż. ņØ┤ļ¤¼ĒĢ£ Ļ▓░ĒĢ®ņØś ņ”ØĻ░ĆļŖö TFTĒŖ╣ņä▒ņŚÉņØś Ē¢źņāüņØä Ļ░ĆņĀĖņś©ļŗż. ļśÉĒĢ£ Ēæ£ļ®┤ņŚÉ ĒØĪņ░®ļÉ£ Peak 3ņØś ĒĢ©ļ¤ēņØ┤ ņś©ļÅäĻ░Ć ļåÆņĢäņ¦Ćļ®┤ 17.17%ņŚÉņä£ 10.17%ļĪ£ ļ¦ÄņØĆ Ļ░ÉņåīĻ░Ć ņØ┤ļŻ©ņ¢┤ ņ¦ĆļŖöļŹ░ ņØ┤ ļśÉĒĢ£ ņĀäņ×Éņåīņ×ÉņØś ĒŖ╣ņä▒ņŚÉ ĻĖŹņĀĢņĀüņØĖ ņśüĒ¢źņØä ņŻ╝ļŖö ņ”ØĻ▒░Ļ░Ć ļÉ£ļŗż. ņś©ļÅäĻ░Ć 300 ┬░CļĪ£ ļåÆņĢäņ¦ÉņŚÉ ļö░ļØ╝ņä£ peak 1ņØś ņ”ØĻ░ĆļŖö M-O latticeņØś ņżæĻ░ĆļĪ£ ņØ┤ļŖö conducting pathwayļĪ£ ņ×æņÜ®ĒĢ£ļŗż. ļśÉĒĢ£ peak 2ņØś Ļ░Éņåīļź╝ ļéśĒāĆļéśļŖöļŹ░ ņØ┤ļŖö oxygen vacancyņŚÉ ņØśĒĢ£ ņśüĒ¢źņ£╝ļĪ£ ļéśĒāĆļéśļŖö Ļ▓āņ£╝ļĪ£ oxygen vacancyļŖö ņÜ┤ļ░śņ×É carrierņŚÉ ņØśĒĢ£ ņØ┤ļÅÖļÅäņŚÉ ĻĖ░ņŚ¼ĒĢ£ļŗż[15]. ļśÉĒĢ£ Li dopingņŚÉ ņØśĒĢśņŚ¼ M-O latticeĻ░Ć ņ”ØĻ░ĆĒĢśļŖö Ļ▓āņØĆ LiņØś ņ×æņØĆ ņØ┤ņś©ļ░śĻ▓ĮņŚÉ ņØśĒĢ£ Ļ▓āņ£╝ļĪ£ ņé¼ļŻīļÉ£ļŗż[9].

TFTļź╝ ņĀ£ņ×æĒĢśĻĖ░ ņ£äĒĢśņŚ¼ ņŗżļ”¼ņĮś ņø©ņØ┤ĒŹ╝ ņ£äņŚÉ ņŚ┤ņé░ĒÖöļĪ£ ĒśĢņä▒ļÉ£ ņé░ĒÖöļ¼╝ņĖĄ ņ£äņŚÉ ņ×ēĒü¼ņĀ»ņ£╝ļĪ£ ļ”¼ĒŖ¼ņØ┤ ļÅäĒĢæ ļÉ£ IZO ļ░śļÅäņ▓┤ņĖĄņØä ĒśĢņä▒ĒĢśņŚ¼ bottom gateņÖĆ top contact ĻĄ¼ņĪ░ņØś TFTļź╝ ņĀ£ņ×æĒĢśņśĆļŗż. ļ”¼ĒŖ¼ņŚÉ ņØśĒĢ£ ļÅäĒĢæļåŹļÅäņŚÉ ņśüĒ¢źņØä ĒÖĢņØĖĒĢśĻĖ░ ņ£äĒĢśņŚ¼ IZOņŚÉ 0.01ņŚÉņä£ 0.1 MņØś ļ”¼ĒŖ¼ņØä ļÅäĒĢæ ĒĢ£ ļ░Ģļ¦ēņØä ņØ┤ņÜ®ĒĢ£ TFTļź╝ ņĀ£ņ×æĒĢśņśĆļŗż. ĻĘĖļ”╝ 4ņŚÉņä£ļŖö inkjet Ļ│ĄņĀĢņ£╝ļĪ£ ņĀ£ņ×æļÉ£ Li-doped TFTņØś ĒŖ╣ņä▒Ļ│ĪņäĀņØĖ transfer curveņÖĆ output curveļź╝ ļ│┤ņŚ¼ņżĆļŗż. LiņŚÉ ņØśĒĢ£ ļÅäĒĢæņØś ņśüĒ¢źņØĆ ņśłņāüļ│┤ļŗż ņ╗żņä£ 0.05ņÖĆ 0.1MņØś ļÅäĒĢæļåŹļÅäņŚÉņä£ļŖö transferņØś ĒŖ╣ņä▒Ļ│ĪņäĀņØä ņ¢╗ņØä ņłś ņŚåņŚłļŗż. ņØ╝ļ░śņĀüņ£╝ļĪ£ Ļ│ĀļåŹļÅäņØś ļÅäĒĢæņØä ĒĢĀ Ļ▓©ņÜ░ņŚÉļŖö substitutional average crystal sizeņÖĆ interplanar spacingņŚÉ ļö░ļØ╝ņä£ TFT ĒŖ╣ņä▒ Ļ░ÆņØś ņĀĆĒĢśļź╝ ņĢ╝ĻĖ░ĒĢ£ļŗż[16].

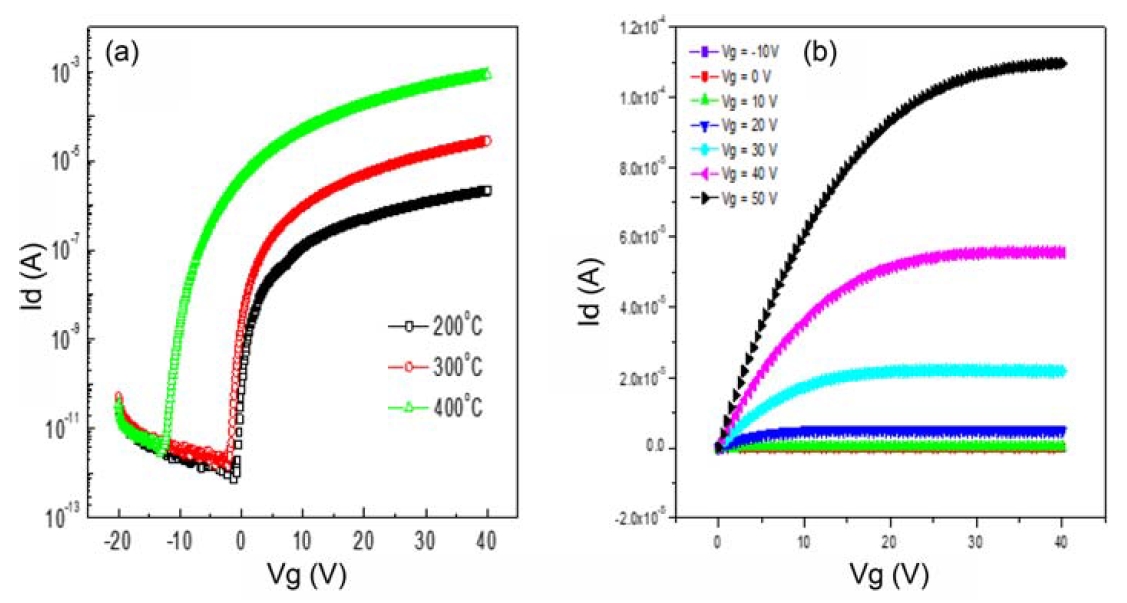

0.01 MņØś Ļ▓ĮņÜ░ņŚÉļŖö ņé░ĒÖöļ¼╝ļ░śļÅäņ▓┤ņØś transfer curveļź╝ ņ¢╗ņ¢┤ ĻĘĖļ”╝ 5ņŚÉ ļéśĒāĆļé┤ņŚłļŗż. ļśÉĒĢ£ ņŚ┤ņ▓śļ”¼ ņś©ļÅäņŚÉ ļö░ļźĖ transfer ĒŖ╣ņä▒ ņé┤Ēæ£ļ│┤ĻĖ░ ņ£äĒĢśņŚ¼ 200-300 ┬░CņØś ņāüļīĆņĀüņ£╝ļĪ£ ļé«ņØĆ ņś©ļÅäņŚÉņä£ TFT ņåīņ×Éļź╝ ņĀ£ņ×æĒĢśņśĆļŗż. ĒØźļ»ĖļĪ£ņÜ┤ Ļ▓āņØĆ ļ¦żņÜ░ ļé«ņØĆ 200 ┬░CņŚÉņä£ļÅä TFTĒŖ╣ņä▒ņØä ņ¢╗ņØä ņłś ņ׳ņŚłļŗż. transfer curveļź╝ ņØ┤ņÜ®ĒĢ£ TFTņØś ĒŖ╣ņä▒ Ļ░ÆņØä ĻĄ¼ĒĢśņŚ¼ Table 2ņŚÉ Ēæ£ņŗ£ĒĢśņśĆļŗż.

0.01%ņØś Li ļÅäĒĢæļÉ£ IZO TFTņØś Ļ▓ĮņÜ░ņŚÉļŖö 400 ┬░CņØś ņś©ļÅäņŚÉņä£ ņØ┤ļÅÖļÅäļŖö 9.08 ┬▒ 0.7 cm2/V s, subthreshold slope (S.S.)ļŖö 0.62 V dec-1, Ion-to-Ioff current ratioļŖö 108, ĻĘĖļ”¼Ļ│Ā ļ¼ĖĒä▒ņĀäņĢĢņØĆ 12.66 Vļź╝ ļéśĒāĆļéĖļŗż. ņś©ļÅäļź╝ 200 ┬░CļĪ£ ļé«ņČöņ¢┤ ņŚ┤ņ▓śļ”¼ļź╝ ĒĢ£ Ļ▓ĮņÜ░ņŚÉļŖö ņśłņāüĒĢśļŖö Ļ▓ā Ļ░ÖņØ┤ ĒŖ╣ņä▒ņĀĆĒĢśļź╝ ĒÖĢņØĖĒĢĀ ņłś ņ׳ļŗż. ņØ┤ļÅÖļÅäļŖö 0.2 ┬▒ 0.08 cm2/V s, subthreshold slope (S.S.)ļŖö 0.3 V dec-1. Ion-to-Ioff current rationļŖö 106, ĻĘĖļ”¼Ļ│Ā ļ¼ĖĒä▒ņĀäņĢĢņØĆ -1.23 Vļź╝ ļéśĒāĆļéĖļŗż (Table 2). ņØ┤ļŖö ļé«ņØĆ ņś©ļÅäņŚÉņä£ļŖö ņÖäņĀäĒĢ£ ĻĖłņåŹ-ņé░ĒÖöļ¼╝ ļ░śņØæņØ┤ ņØ╝ņ¢┤ļéśņ¦Ć ļ¬╗ĒĢśĻĖ░ ļĢīļ¼Ėņ£╝ļĪ£ ļ░Ģļ¦ēļé┤ņŚÉ ņłś ļ¦ÄņØĆ ņ£ĀĻĖ░ļ¼╝Ļ│╝ ļ»Ė ļ░śņØæ ļ¼╝ņ¦łņØ┤ ņ׳Ļ│Ā ļČłņÖäņĀäĒĢ£ ĻĖłņåŹ ņé░ĒÖöļ¼╝ Ļ▓░ĒĢ®ņŚÉ ņØśĒĢ£ ņłś ļ¦ÄņØĆ Ļ▓░ĒĢ©ņØ┤ ņĪ┤ņ×¼ĒĢśĻĖ░ ļĢīļ¼ĖņØ┤ļŗż. ĻĖ░ņĪ┤ņØś Ļ▓ĮņÜ░ņŚÉļŖö ņØ┤ņÖĆ Ļ░ÖņØ┤ ļé«ņØĆ ņś©ļÅäņŚÉņä£ ņÜ®ņĢĪĻ│ĄņĀĢņØ┤ļéś ņØĖņćäĻ│ĄņĀĢņŚÉ ņØśĒĢ£ TFTņØś ĒŖ╣ņä▒ņØä ņ¢╗ĻĖ░ļŖö ņēĮņ¦ĆņĢŖļŗż. ļÅäĒĢæņØ┤ ņŚåļŖö IZO TFTļź╝ inkjet printingņ£╝ļĪ£ ņĀ£ņ×æĒĢ£ Ļ▓ĮņÜ░ņŚÉļŖö 200 ┬░CņŚÉņä£ ņ£Āņé¼ĒĢ£ TFTĒŖ╣ņä▒ņØä ņ¢╗ņŚłĻ│Ā, 400 ┬░CņŚÉņä£ļŖö ņØ┤ļÅÖļÅäļŖö 3.54 cm2/V s, S.S.ļŖö 1.0 V dec-1. Ion-to-Ioff current rationļŖö 105, ĻĘĖļ”¼Ļ│Ā ļ¼ĖĒä▒ņĀäņĢĢņØĆ -3.2 VņØś Ļ▓░Ļ│╝ļź╝ ļ░£Ēæ£ĒĢśņśĆļŗż[8]. ņ”ē ļ”¼ĒŖ¼ņØś ļÅäĒĢæņŚÉ ņØśĒĢ£ Ļ▓ĮņÜ░ņŚÉļŖö ļÅäĒĢæņØ┤ ņŚåļŖö Ļ▓ĮņÜ░ ļ│┤ļŗżļÅä TFTĒŖ╣ņä▒ Ļ░ÆņØ┤ ļŹö ļåÆņØĆ ņØ┤ļÅÖļÅäņÖĆ ņĀäļźśĒŖ╣ņä▒ļ╣äļź╝ ņ¢╗ņØä ņłś ņ׳ņŚłļŗż. ņØ┤ļŖö ļÅäĒĢæ ļÉ£ ļ”¼ĒŖ¼ņØĆ ļ░śļÅäņ▓┤ļé┤ņŚÉņä£ shallow donorņØś ņŚŁĒĢĀņØä ĒĢśņŚ¼ ņåīņ×ÉņØś ĒŖ╣ņä▒ņŚÉ ĻĖ░ņŚ¼ĒĢśļŖö Ļ▓āņ£╝ļĪ£ ņé¼ļŻīļÉ£ļŗż. InkjetņØä ņØ┤ņÜ®ĒĢ£ ņé░ĒÖöļ¼╝ ļ░Ģļ¦ēņØś ĒśĢņä▒ņŚÉņä£ļŖö jetting ņĪ░Ļ▒┤ņŚÉ ļö░ļźĖ ļ░Ģļ¦ēņØś ĒśĢņä▒ņØś ņśüĒ¢źņØ┤ Ēü¼Ļ│Ā, ĒŖ╣Ē׳ ņĀäņĢĢņØś ņśüĒ¢źņŚÉ ļö░ļźĖ ĒÜ©Ļ│╝ņÖĆ ņŻ╝ĒīīņłśņŚÉ ļö░ļźĖ ĒÜ©Ļ│╝ļź╝ ņל ņĪ░ĒĢ®ĒĢśņŚ¼ ņĄ£ņĀüĒÖöĒĢĀ ĒĢäņÜöĻ░Ć ņ׳ļŗż. ņØ┤ņÖĆ Ļ░ÖņØ┤ ļé«ņØĆ ņś©ļÅäņŚÉņä£ņØś TFTĒŖ╣ņä▒ņØä ņ¢╗ļŖö ņ”ØĻ▒░ļź╝ XPSņŚÉņä£ļÅä ĒÖĢņØĖĒĢĀ ņłś ņ׳ļŖöļŹ░, ņØ┤ļŖö 200 ┬░CņŚÉņä£ļÅä ĻĖłņåŹ-ņé░ĒÖöļ¼╝ņØ┤ ĒśĢņä▒ļÉ©ņ£╝ļĪ£ ĒÖĢņØĖĒĢĀ ņłś ņ׳ļŗż. 400 ┬░CņØś ņś©ļÅäņŚÉņä£ ņ¢╗ņØĆ ņÜ░ņłśĒĢ£ TFTĒŖ╣ņä▒ņØĆ metal-oxide formationņŚÉ ņØśĒĢ£ ĻĖłņåŹ ņé░ĒÖöļ¼╝ņØś ĒśĢņä▒ņØ┤ ņ”ØĻ░ĆļÉśĻ│Ā, ņÖĖņĀüņØĖ ņśüĒ¢źņŚÉ ņØśĒĢ£ Ļ▓āņ£╝ļĪ£ OohņØś Ļ░ÉņåīņÖĆ ļŗ¼ļØĮņĖĄņŚÉ ĻĖ░ņØĖĒĢ£ Ļ▓āņ£╝ļĪ£ ĒÖĢņØĖļÉ£ļŗż.

ĻĘĖļ”╝ 4(b)ņŚÉņä£ļŖö ļ”¼ĒŖ¼ ļÅäĒĢæņŚÉ ņØśĒĢ£ IZO TFTņØś output curveņØ┤ļŗż. Output ĒŖ╣ņä▒ņŚÉņä£ļŖö contact ņāüĒā£Ļ░Ć ņåīņŖżņÖĆ ļō£ļĀłņØĖĻ│╝ ļ░śļÅäņ▓┤ņØś ņĀæņ┤ēņØ┤ ņלļÉśņ¢┤ ņ׳ļŗżļŖö Ļ▓āņØä ļéśĒāĆļé┤ļ®░, ļśÉĒĢ£ Ļ▓īņØ┤ĒŖĖ ņĀäņĢĢņŚÉ ļö░ļźĖ ļō£ļĀłņØĖ ņĀäņĢĢņØś ņ”ØĻ░ĆņŚÉ ļö░ļØ╝ ļō£ļĀłņØĖ ņĀäļźśĻ░Ć ĒżĒÖö ĒŖ╣ņä▒ņØä ņČ®ļČäĒ׳ ļ│┤ņŚ¼ņŻ╝ļŖö Ļ▓āņØä ĒÖĢņØĖĒĢĀ ņłś ņ׳ļŗż.

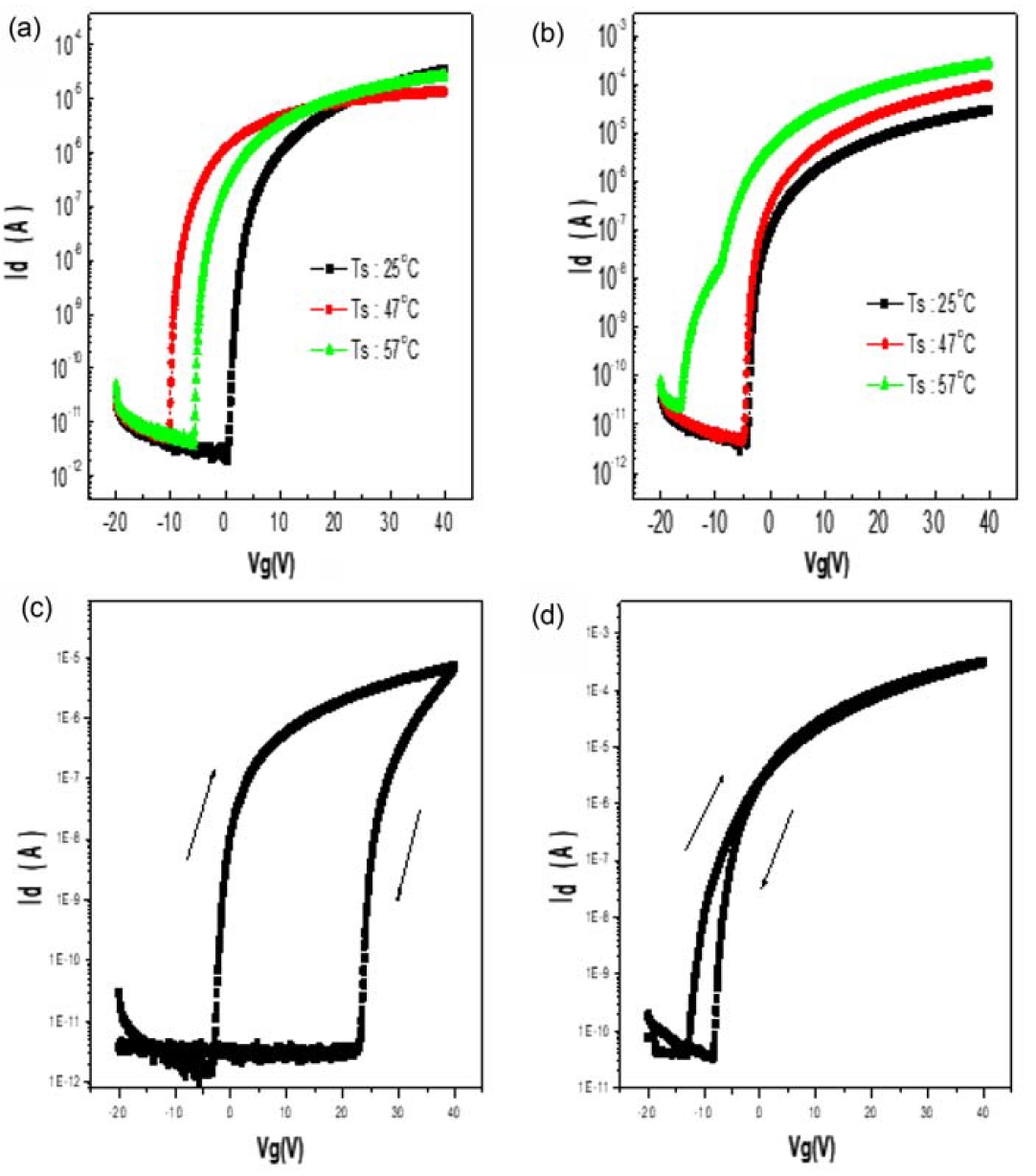

ĻĘĖļ”╝ 5ņŚÉņä£ņÖĆ Ļ░ÖņØ┤ ĻĖ░ĒīÉņś©ļÅäņŚÉ ļö░ļźĖ TFTņØś ĒŖ╣ņä▒ņØä ņé┤ĒÄ┤ļ│┤ņĢśļŗż. 200 ┬░CņØś ļé«ņØĆ ņŚ┤ņ▓śļ”¼ ņś©ļÅäņŚÉņä£ inkjet ņØĖņćäņØś ĻĖ░ĒīÉ ņś©ļÅäļź╝ 25, 47, ĻĘĖļ”¼Ļ│Ā 57 ┬░CļĪ£ ļ│ĆĒÖöĒĢśņśĆņØä Ļ▓ĮņÜ░ņŚÉļŖö ņØ┤ļÅÖļÅäļŖö 0.33 ņŚÉņä£ 0.20 cm2/V sņØś Ļ░ÆņØä ļéśĒāĆļé┤Ļ│Ā, onto-off current ļ╣äņ£©ņØĆ 106ņŚÉņä£ 107ņØś Ļ░ÆņØä ļéśĒāĆļé┤Ļ│Ā, S.S.ņØĆ 0.2ņŚÉņä£ 0.6 V.dceņØś Ļ░ÆņØä ļéśĒāĆļéĖļŗż. ļīĆņ▓┤ņĀüņ£╝ļĪ£ ĻĖ░ĒīÉņś©ļÅäņØś ņśüĒ¢źņØĆ ņĀüņØĆ ĒÄĖņØ┤ļŗż. ĒĢ£ĒÄĖ ļ¼ĖĒä▒ņĀäņĢĢņØĆ ĻĖ░ĒīÉņØś ņś©ļÅäĻ░Ć ņś¼ļØ╝Ļ░Ćļ®┤ņä£ 4.4 VņŚÉņä£ -3.1 VļĪ£ ļ│ĆĒÖöļÉśļŖö Ļ▓āņØä ņĢī ņłś ņ׳ļŗż.

ņØ┤ļŖö TFTĻ░Ć enhancement modeņŚÉņä£ depletion modeļĪ£ņØś ļ│ĆĒÖöĻ░Ć ņØ╝ņ¢┤ļé©ņØä ņĢī ņłś ņ׳ļŗż. ņØ┤ļŖö Ēæ£ļ®┤ņŚÉ ĒØĪņ░®ļÉ£ ņé░ņåīĻ░Ć ņ▒äļäÉņŚÉņä£ ņĀäņ×Éļź╝ ļüīņ¢┤ļŗ╣Ļ▓©ņä£ ĻĘĖ ņśüņŚŁņŚÉ depletionņØ┤ ļ░£ņāØĒĢśĻĖ░ ļĢīļ¼ĖņØ┤ļŗż[8]. ļśÉĒĢ£ ļ¼ĖĒä▒ņĀäņĢĢņØś shiftļŖö ļæÉĻ╗śņŚÉ ļö░ļźĖ trap densityņØś ņ”ØĻ░ĆņŚÉ ĻĖ░ņØĖĒĢ£ļŗż[17].

ĻĘĖļ”╝ 5(c)ņÖĆ 5(d)ļŖö ļ”¼ĒŖ¼ņØ┤ ļÅäĒĢæ ļÉ£ IZO TFTņØś transfer curveņŚÉņä£ņØś hysteresis ĒŖ╣ņä▒Ļ│ĪņäĀņØä ļ│┤ņŚ¼ņŻ╝Ļ│Ā ņ׳ļŗż.

HysteresisļŖö ņŗ£Ļ│äļ░®Ē¢ź (ņ¢æļ░®Ē¢ź)ņ£╝ļĪ£ņØś ļ│ĆĒÖöĻ░Ć ļéśĒāĆļéśļŖöļŹ░, ņŗ£Ļ│äļ░®Ē¢źņ£╝ļĪ£ ļéśĒāĆļéśļŖö ņØ┤ļ¤¼ĒĢ£ hysteresis ĒśäņāüņØĆ Ļ▓īņØ┤ĒŖĖ ņĀłņŚ░ņ▓┤ņÖĆ ļ░śļÅäņ▓┤ ņé¼ņØ┤ņØś Ļ│äļ®┤ ļśÉļŖö ļ░śļÅäņ▓┤ņŚÉņä£ ņØ╝ņ¢┤ļéśļŖö ņĀäņ×ÉņØś trapņŚÉ ņØśĒĢ£ Ļ▓āņ£╝ļĪ£ ņØ╝ļ░śņĀüņØ┤ ņé░ĒÖöļ¼╝ļ░śļÅäņ▓┤ļź╝ ņØ┤ņÜ®ĒĢ£ TFTņŚÉņä£ ļéśĒāĆļéśļŖö ĒśäņāüņØ┤ļŗż[18]. ĻĘĖļ”╝ 5(c)Ļ░Ć 200 ┬░C ļØ╝ļŖö ļé«ņØĆ ņś©ļÅäļØ╝ļŖö Ļ▓āņØä Ļ│ĀļĀżĒĢśļ®┤ ņØ┤ņÖĆ Ļ░ÖņØĆ hysteresis ĻĘĖļ”¼Ļ│Ā output ĒŖ╣ņä▒ņØĆ ĻĖ░ļīĆļ│┤ļŗżļÅä ņ¢æĒśĖĒĢ£ Ļ▓āņ£╝ļĪ£ ĒÅēĻ░ĆļÉĀ ņłś ņ׳ļŗż. ņś©ļÅäĻ░Ć 300 ┬░CļĪ£ ņś¼ļØ╝Ļ░Ćļ®┤ hysteresis ĒśäņāüņØ┤ Ēü¼Ļ▓ī ņżäņ¢┤ļōżņ¢┤ ļ¦żņÜ░ ņ¢æĒśĖĒĢ£ ĒŖ╣ņä▒ Ļ░ÆņØä ļéśĒāĆļéĖļŗż. ņØ┤ļŖö ņś©ļÅäņŚÉ ņØśĒĢśņŚ¼ Ļ│äļ®┤ņØś ņĀäņ×É trapĻ│╝ defectļō▒ņØ┤ ņżäņ¢┤ļōżĻĖ░ ļĢīļ¼ĖņØ┤ļŗż.

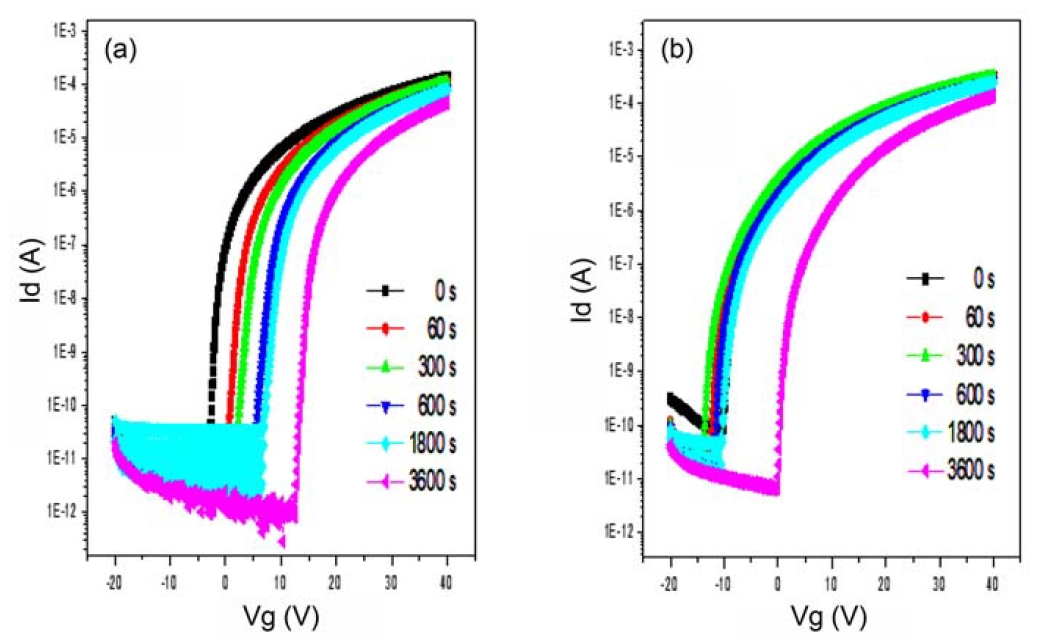

ĻĘĖļ”╝ 6ļŖö ņ¢æņĀäĒĢś ļČĆĒĢś ņĢłņĀĢņä▒(positive bias stress stability)ņØä ĒÖĢņØĖĒĢśĻĖ░ ņ£äĒĢśņŚ¼ TFTņŚÉ ņØ╝ņĀĢĒĢ£ ņĀäņĢĢņØä ņןņŗ£Ļ░ä ļČĆņŚ¼ĒĢśņśĆņØä ļĢīņØś TFTņØś transfer curveņØś ļ│ĆĒÖöļź╝ ļ│┤ņŚ¼ņŻ╝Ļ│Ā ņ׳ļŗż.

Bias stressļŖö ņŗ£Ļ░äņŚÉ ļö░ļØ╝ņä£ ņśżļźĖņ¬Į (ņ¢æ) ļ░®Ē¢źņ£╝ļĪ£ņØś ņØ┤ļÅÖņØ┤ Ļ┤Ćņ░░ļÉ£ļŗż. ļö░ļØ╝ņä£ ļ¼ĖĒä▒ņĀäņĢĢļÅä transfer curveņØś ņØ┤ļÅÖņŚÉ ļö░ļØ╝ ņśżļźĖņ¬Į ļ░®Ē¢źņ£╝ļĪ£ ņØ┤ļÅÖĒĢ£ļŗż. ņØ┤ļ¤¼ĒĢ£ ņ¢æņĀäĒĢśņØś ļČĆĒĢśņŚÉ ļö░ļźĖ transfer curveņØś ņ¢æņØś ļ░®Ē¢źņ£╝ļĪ£ņØś ņØ┤ļÅÖņØĆ Ļ▓īņØ┤ĒŖĖ ņĀłņŚ░ņ▓┤ņÖĆ ļ░śļÅäņ▓┤ņØś Ļ│äļ®┤ņŚÉņä£ ņØīņØ┤ņś©ņØś trap ĒśäņāüņØ┤ ņØ╝ņ¢┤ļéśĻĖ░ļĢīļ¼Ėņ£╝ļĪ£ ņĢīļĀżņĀĖ ņ׳ļŗż[17]. ĒĢ£ĒÄĖ 200 ┬░CņØś ļé«ņØĆ ņŚ┤ņ▓śļ”¼ ņś©ļÅäņŚÉņä£ļŖö bias stressņØś ņśüĒ¢źņØ┤ ļŹö ņ╗żņä£ ņ¢æņØś ļ░®Ē¢źņ£╝ļĪ£ņØś ņØ┤ļÅÖņØ┤ 300 ┬░CņØś Ļ▓ĮņÜ░ļ│┤ļŗżļÅä ļ¦ÄņØ┤ ļ░£ņāØĒĢ£ļŗż. ņØ┤ļŖö ļ»Ė ļ░śņØæņä▒ ņ×öļźśļ¼╝ņ¦łĻ│╝ ļ╣ä Ē£śļ░£ļÉ£ ņ×öļźśļ¼╝ņ¦ł, ĻĘĖļ”¼Ļ│Ā ļČłņĢłņĀäĒĢ£ ĻĖłņåŹ ņé░ĒÖöļ¼╝ņØś ĒśĢņä▒ņŚÉ ņØśĒĢśņŚ¼ ņāØņä▒ļÉ£ ļŗżļ¤ēņØś Ļ▓░ĒĢ© ļō▒ņ£╝ļĪ£ ņØĖĒĢ£ ņĀäĒĢśĻ░Ć ĒŖĖļ×®ļÉśļŖö ĒśäņāüņØ┤ ļ¦ÄņØ┤ ļ░£ņāØļÉśņ¢┤ TFTņåīņ×ÉņØś ĒŖ╣ņä▒ Ļ░ÆņŚÉ ļ¦ÄņØĆ ņśüĒ¢źņØä ņŻ╝ļŖö Ļ▓āņØä ĒÖĢņØĖ ĒĢĀ ņłś ņ׳ļŗż.

4. Ļ▓░ ļĪĀ

ņĀĆņś©ņŚÉņä£ Inkjet printing Ļ│ĄņĀĢņØä ņØ┤ņÜ®ĒĢśņŚ¼ ņé░ĒÖöļ¼╝ IZO TFTļź╝ ņĀ£ņ×æĒĢ£ Ļ▓ĮņÜ░ņŚÉ ņ▓©Ļ░ĆņĀ£ļĪ£ņä£ ļ”¼ĒŖ¼ņØś ļåŹļÅäņŚÉ ļö░ļźĖ TFTņåīņ×ÉņØś ĒŖ╣ņä▒ņØä Ļ┤Ćņ░░ĒĢśņśĆļŗż. Ļ│ĄņĀĢ ņś©ļÅäĻ░Ć ļé«ņØä Ļ▓ĮņÜ░ļéś ļÅäĒĢæļÉ£ ļ”¼ĒŖ¼ņØś ņ¢æņØ┤ ļåÆņØĆ Ļ▓ĮņÜ░ņŚÉļŖö ņåīņ×ÉņØś ĒŖ╣ņä▒ņØ┤ ĻĄ¼ĒśäļÉśņ¦Ć ņĢŖņĢśļŗż. 0.01 MņØś ļ”¼ĒŖ¼ņØä ļÅäĒĢæĒĢ£ Ļ▓ĮņÜ░ņŚÉ, 200 ┬░CņØś ņĀĆņś©ņŚÉņä£ inkjet-printed Li-doped IZO TFT ņåīņ×ÉļŖö TFTņØś ĒŖ╣ņä▒ņØĆ ņØ┤ļÅÖļÅäļŖö 0.2 ┬▒ 0.08 cm2/V s, S.S.ļŖö 0.3 V dec-1. ĻĘĖļ”¼Ļ│Ā Ion-to-Ioff current rationļŖö 106 Vļź╝ ļéśĒāĆļéĖļŗż. Ļ│ĄņĀĢņś©ļÅäĻ░Ć 400 ┬░CņØś Ļ▓ĮņÜ░ņŚÉļŖö ņØ┤ļÅÖļÅä 9.08 ┬▒ 0.7 cm2/V s, ļ¼ĖĒä▒ņĀäņĢĢ 2.66 V, on-to-off current ratio of 2.83 ├Ś 108, ĻĘĖļ”¼Ļ│Ā S.S. sub-threshold slope 0.62 V/decļź╝ Ļ░¢ļŖö Ļ▓āņ£╝ļĪ£ ĒÖĢņØĖĒĢśņśĆļŗż. ļÅäĒĢæļÉ£ ļ”¼ĒŖ¼ņØĆ ļ░śļÅäņ▓┤ ļé┤ņŚÉņä£ shallow donorļĪ£ņä£ TFTĒŖ╣ņä▒ņØś Ļ░£ņäĀņŚÉ ĻĖ░ņŚ¼ĒĢśņśĆļŗż. ļśÉĒĢ£ ļ”¼ĒŖ¼ņØś ļÅäĒĢæņŚÉ ņØśĒĢśņŚ¼ hysteresisņÖĆ ņ¢æņĀäĒĢśņØś ļČĆĒĢś(positive bias stability)ņŚÉ ļīĆĒĢ£ ĒŖ╣ņä▒ļÅä Ļ░£ņäĀļÉ©ņØä ĒÖĢņØĖĒĢśņśĆļŗż.